In recent years, technological introductions within the Food & Beverage industry have led to a considerable increase in production, as well as a rise in exports worldwide.

More and more companies rely on Automation to improve their production chains, making them fast and efficient.

The main difference with manual production is the absence of so-called "human error". Once you enter the correct parameters, you will always get the same product without defects and without waste.

Advantages of Automation

The world of Automation was born to "help" man's work, to simplify it and at the same time make it more precise.

Specifically, by relying on automated production systems you will be able to work while saving money: you will keep energy savings under control, since the systems will start up and operate only when they are strictly necessary. In the same way you will save the money needed for labour, since the software itself will take care of the work.

This means that the money paid to "automate" your business will return very quickly, allowing you to increase your profit in the long term.

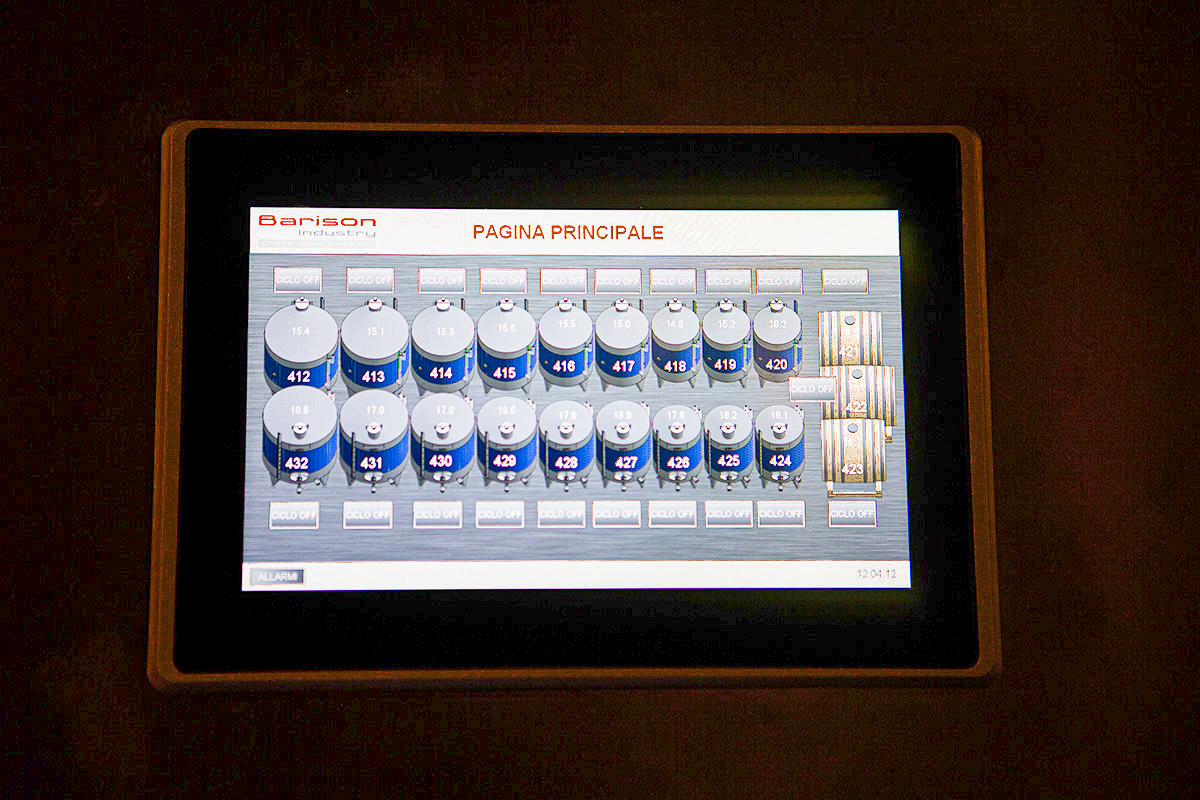

In addition, Automation provides easy to use systems. The new interfaces proposed are intuitive and suitable even for less experienced figures. You will be able to customise the timing and production methods, ensuring that they adapt perfectly to your needs.

Automation allows you to manage several plants of the same production process at the same time, through a network communication. It does not matter what kind of management control the plant has, it will still be connected to the system creating a lean and communicating production chain.

The automation process is scalable over time, i.e. it is possible to automate a first part of the plant and then the remaining part. For example: a winery can automate part of the production and then integrate the system with the remaining plants.

In most cases, it is possible to control the automation via apps downloaded on the smartphone or tablet.

In this way you can switch off and start the different production processes directly from remote and manage any problems. In fact, if an error occurs, the app reports it in the form of an alarm.

For more serious problems, when the integrity of the system is put at risk, the system directly blocks the system to avoid unpleasant situations.

Automation helps prevent damage, transmitting a constantly updated diagnostics that helps to avoid unwanted problems. In addition, the same assistance becomes faster; the supplier does not need to come directly to the plant to understand what has happened but can monitor the systems and software directly from remote, transmitting information to the customer quickly.

Can Automation and Customization Live Together?

Several users, before experiencing Automation, are overwhelmed by various doubts. They wonder if the final product is not impersonal, or in any case far from the original appearance, through the use of technological means.

The answer to this question is actually quite simple. Automation does not lead to depersonalisation but, on the contrary, raises it to the nth power by speeding up production. The parameters entered are in any case personal and change from user to user. Your recipes remain intact, only they are reproduced on a large scale and allow you to save time and labour.

Therefore, Automation is not the antipode of artisan production, but simply an evolution of it. Learning to exploit these new technologies can only benefit the activities and their owners.

Do you want to get a free consultation

for the study and planning of a customized system?

Leave your details to receive a free consultation We'll get back to you in a few hours!

Alternatively you can contact us at +39 0461 1788800